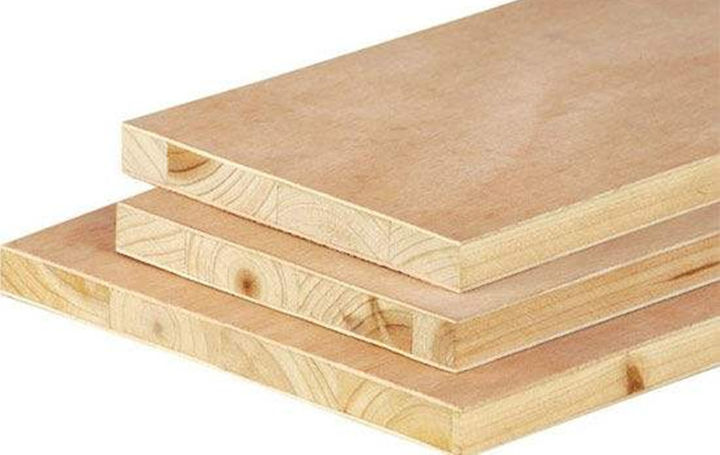

Blockboard

blockboard wood (commonly known as big core board) is a plywood with a solid wood core. Its vertical (differentiated by the direction of the core board) has poor flexural and compressive strength, but its transverse flexural and compressive strength is higher. Most of the current market is solid, glued, double-sided sanding, five-layer blockboard, which is one of the most commonly used boards.

Advantages of blockboard:

A. Blockboard has good screw holding power, high strength, strong quality, sound absorption, heat insulation, etc. The blockboard has a low moisture content, between 10% and 13%, and is easy to process. It is used for furniture, doors and windows. And covers, partitions, false walls, heating covers, curtain boxes, etc.

B. Because the interior is made of solid wood strips, the requirements for processing equipment are not high, which is convenient for on-site construction.

Disadvantages:

A. Because wood board uses a large amount of urea-formaldehyde glue in the production process, the formaldehyde emission is generally high, and the environmental protection standard is generally low. This is why most plyboard tastes pungent.

B. At present, most of the joinery board on the market cut corners in the production. The gap is large when the solid wood strips are spliced, and there are cavities in the board. If nails are nailed in the gap, there is basically no nail holding power.

C. The solid wood strips inside the plyboard wood are longitudinally spliced, so the vertical bending and compressive strength is poor, and long-term stress will cause obvious lateral deformation of the board.

D. The solid wood strips inside the ply boards 8x4 have different materials and different densities. After a simple drying process, they are easy to warp and deform; the structure is distorted and deformed, which affects the appearance and use effect.

E. Because the surface of wood board is relatively rough, a lot of glue or paint is usually used when processing the surface at the woodworking site. Therefore, the furniture made from this board is extremely environmentally friendly. This is the main reason why the smell is very irritating during decoration. The reason is that such on-site furniture is the culprit for carcinogenesis and gene mutation, and it is very harmful to the human body.

Particle board

chipboard plywood is made by cutting various branches and buds, small diameter wood, fast-growing wood, sawdust, etc. into fragments of a certain specification, after drying, mixing with rubber, hardener, waterproofing agent, etc, and pressing it under a certain temperature and pressure. A kind of man-made board, because its section resembles honeycomb, so it is called particle board.

Adding certain "moisture-proof factor" or "moisture-proofing agent" and other raw materials inside the e1 grade particle board becomes what people usually call moisture proof particle board, referred to as moisture resistant mdf board. It has a certain moisture-proof effect because the particle board itself has strong moisture-proof performance and absorbs water. The post-expansion coefficient is small, and it is commonly used in cabinets, bathroom cabinets and other environments, but in reality, it has become a tool for many inferior mfc particle board to cover up internal impurities.

Adding green coloring agent inside the grade a hardwood particle board forms what is currently said in the market as the green-based particleboard. Many manufacturers use it to mislead as a green board, but there is no scientific basis for it. In fact, most of the 18mm particle board of top brands at home and abroad are natural base materials.

Advantages:

A. It has good sound absorption and sound insulation performance; 18mm particle board price heat insulation and sound absorption

B. The inside is a granular cross-scattered structure, the performance of each direction is basically the same, the structure is relatively uniform, so the nail holding force is general, and the lateral bearing capacity is good

C. The hardwood particle board has a flat surface, realistic texture, uniform bulk density, small thickness error, pollution resistance, aging resistance, beautiful appearance, and can be painted and various veneers

D. In the production process of particleboard, the amount of glue used is small, and the environmental protection coefficient is relatively high.

Disadcantages:

A. The inside is a granular structure, which is not easy to be milled

B. It is easy to cause tooth-breaking phenomenon when cutting boards, so the requirements for processing equipment are higher

Fiberboard (also called density board)

mdf fiberboard is made of plant fiber as the main raw material, and is made through processes such as hot grinding, sizing, paving, and hot pressing. fiberboard waterproof is divided into density. The density below 450 kg/m3 is called low density fiberboard, and the density between 450-800 kg/m3 is called medium density fiberboard (abbreviated as MDF), and the density is 800 kg/m3. The ones above cubic meters are called high density fiberboard (abbreviated as HDF). MDF is mainly used for the production of finished furniture, but also used for laminate flooring, door panels, partition walls, etc.

Advantages:

A. The surface of the 4x8 fiberboard is smooth and flat, and the material is fine, which is convenient for modeling and milling.

B. The toughness of the fiberboard is better, and it is not easy to break when the thickness is small (such as 6mm, 3mm).

Disadvantages:

A. Fiberboard has poor moisture resistance, and has a larger expansion coefficient after absorbing water

B. The inside of the fiberboard is a powdery structure, and the nail holding force is poor, and the screws are easy to loosen after tightening.

C. Since the strength of mdf fiberboard is not high, the height of the furniture cannot be too high, most of which are 2100mm

E. medium density fiberboard manufacturers in the production of fiberboard, due to its internal structural characteristics, the amount of glue used is large, and to a certain extent, the environmental protection coefficient is low.

Finger joint board

finger-jointed board, also known as laminated board, finger joint timber, which is a board formed by splicing small pieces of deep-processed solid wood like "fingers". Because of the serrated interface between the boards, it resembles the fingers of two hands cross butt, so it is called finger joint board. Because the log strips are cross-bonded, the bonding structure itself has a certain bonding strength, and because there is no need to stick the surface boards up and down, the amount of glue used is very small.

Advantages:

Since there are fewer joints of solid wood splicing boards, and less glue is used, the environmental protection factor is relatively high. It is easy to process and can be cut, drilled, sawed and shaped.

Disadvantages:

The solid wood finger joint board is easy to deform and crack. The quality of good solid wood finger joint board is guaranteed but the cost is higher.

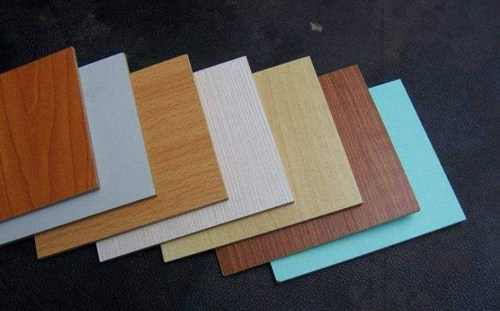

Melamine faced mdf

melamine mdf board is to print the pattern on the surface of the decorative paper, immerse it in melamine glue to make the melamine facing paper, and then heat it on the board substrate at high temperature. Because of 12mm melamine board has high requirements for the flatness of the substrate surface of the board, it is usually used for the surface finish of particle board and medium-density fiberboard. This type of board with melamine pressure-laminated finish is usually called melamine mdf sheets. The surface texture is realistic, wear-resistant, scratch-resistant, and has good water resistance. It is suitable for production and is mainly used for manufacturering panel furniture.

The decorative paper of melamine mdf board is divided into thickness (gram weight), imported paper and domestic paper, and the surface printing ink is divided into imported ink and domestic ink. The effect is also very different.

According to the different dipping process, it is divided into full triamine glue and half triamine glue. The wear resistance coefficient of half triamine is not as good as that of full triamine.

According to the different steel plates when the decorative paper is hot pressed, it is divided into different effects such as smooth surface, hemp surface, embossed surface, cloth pattern, corrugated surface, rain silk surface and so on.

More furniture grade mdf products