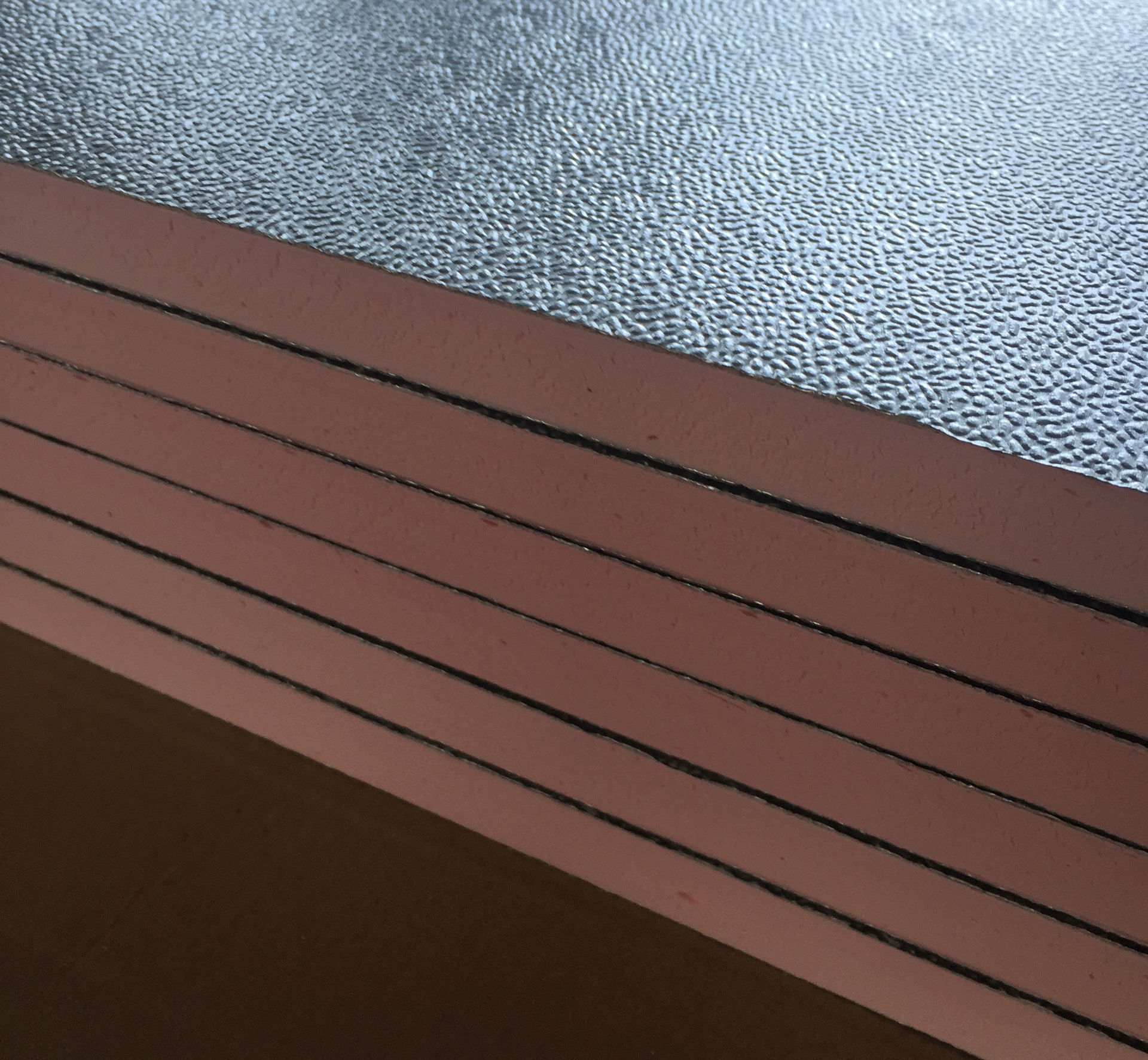

What material is phenolic board?

The phenolic board is made of phenolic foam material, which is a polymer organic hard aluminum foil foam product, foamed by thermosetting phenolic resin. Phenolic foam is known as the "King of Thermal Insulation Materials" and is a new generation of thermal insulation, fire protection and sound insulation materials. It has the properties of light weight, fire resistance, non-burning in open flame, smokeless, non-toxic, non-drip, etc and has a wide temperature range of use.

How to divide the fire rating of phenolic plywood?

phenolic plywood near me is a class B1 material. However, it is non-flammable when exposed to open flames, low smoke, non-toxic, and no drips, so the phenolic plywood belongs to the equivalent A grade. It's just that the oxygen index level currently does not meet the national requirements, but high bulk density or the addition of inorganic materials can also meet the A-level standard, but the phenolic plywood price is slightly more expensive.

Phenolic ply construction technology

1. Basic wall treatment

The wall surface should be cleaned without floating dust, oil stains and other attachments that hinder the adhesion. After the base wall is qualified, hang the vertical and horizontal lines, and apply the cement mortar leveling layer. The leveling layer shall be plastered in layers.

2. Wall hanging line

Hang vertical reference control lines at the yin and yang corners of the building’s external walls and other necessary places, and hang horizontal lines at appropriate positions on each floor to control the verticality and flatness of the insulation board.

3. Preparation of special binder

According to the requirements of the product manual, it is required to stir evenly, with a moderate consistency, and to ensure that the interface agent has a certain viscosity. It can be used after stirring again after standing for a few minutes.

4. Paste the insulation board

Special cutting tools are used to cut the insulation board on site, but it must be noted that the cut is perpendicular to the board surface. Tear off the protective film on the insulation board, and evenly smear the special interface adhesive about 5mm thick on the board, and then use a triangular nail rake to pull the special interface agent into a rake shape, and immediately paste the insulation board on the wall. Squeeze gently and evenly, and use a 2m ruler and rubber hammer to adjust to ensure that its verticality and flatness meet the requirements.

5. Install anchor bolts

After the phenolic plywood is pasted, the anchor bolts should be punched after the adhesive is fully solidified, and the casing should be installed. The anchor bolts around the yin and yang corners, under the cornice, and the edges of the holes should be densely arranged.

6. Wipe the surface layer construction

After the phenolic plywood is installed and checked and accepted, the anti-cracking mortar is applied to the surface layer construction. The surface layer plastering adopts two plastering constructions of the bottom layer and the surface layer. After the steel mesh paving is completed and passed the inspection, the surface layer anti-cracking mortar is applied before the bottom anti-cracking mortar is set.

Phenolic plywood 18mm use

1. Phenolic foam was early used in the insulation of missiles and rocket heads.

2. It is widely used in high-rise buildings, transportation, ships, aviation, space technology and other fields.

3. Pipe and shell products cut by phenolic insulation board are also widely used in the field of pipe insulation such as petrochemical industry.

4. The composite products of phenolic insulation board are used in large-mold built-in systems in building insulation projects, a-level fire insulation systems, integrated building wall insulation and decoration systems, fire door interlayers, color steel sandwich panel houses and other fields.

Disadvantages of phenolic film plywood

1. The fire resistance grade is B grade, up to A2 grade, but the cost is increased.

2. The operating temperature is -60℃~150℃, and it cannot be used under high temperature. In theory, it will resist high temperature distorting.

3. The physical properties are not ideal, the overall adhesion is not good, and the compressive and flexural resistance is extremely low. It is not suitable for every kind of insulation project.

4. High cost and high price.

5. Organic matter is unlikely to be resistant to aging. The long-term effects of ultraviolet rays and other rays will cause the phenolic insulation board to lose its function and shorten its life.

6. Polluting the environment. Because phenol and formaldehyde are used in the production process, the production of phenol and formaldehyde is a highly polluting project.

7. Different phenolic board supplier have different product improvement methods, and product quality varies greatly.

Is phenolic board poisonous?

Phenolic fireproof insulation board is non-toxic. Phenolic molecules only contain carbon, hydrogen, and oxygen atoms. When subjected to high temperature decomposition, apart from a small amount of CO gas, no other toxic gases will be produced.