The materials are mainly divided into pine, pine mixed wood, poplar, and poplar mixed wood.

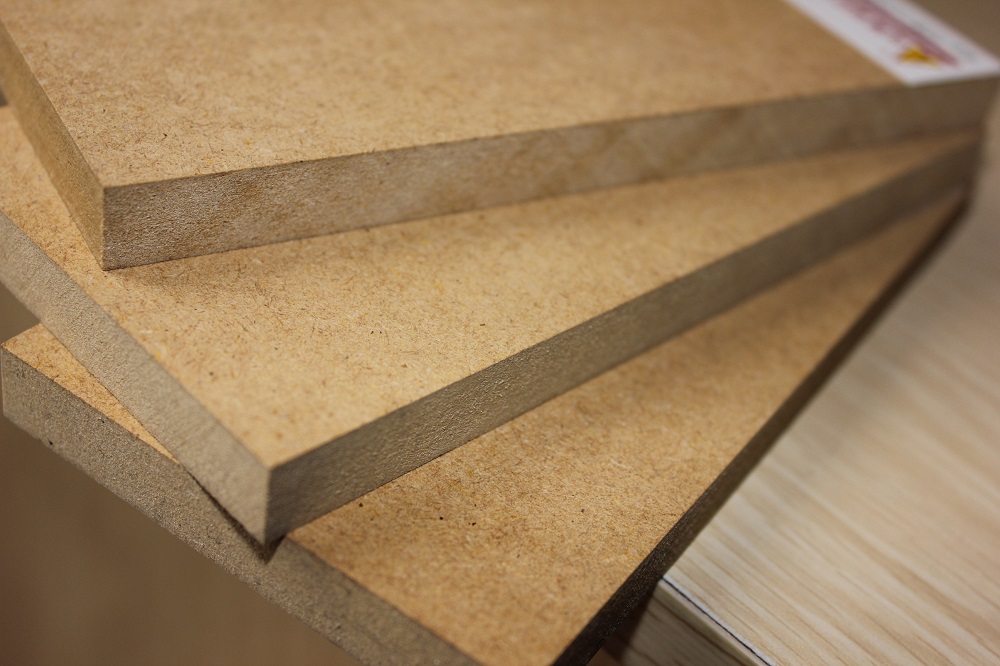

Pine MDF

One of the high-end MDF, with high-quality pine as the raw material, qualified pine mdf produced by a regular manufacturer.

Advantages:

Pine veneer mdf is bright golden yellow, with fine fiber, good oiliness, stable core structure, uniform density and overflowing rosin. Internal bonding strength, nail holding power and other physical properties are excellent, can be carved, milled, no burrs after milling, no sanding, strong adsorption to paint, suitable for all kinds of craft wood products, decorative decoration, the material of choice for high-end furniture in manufacturing.

Disadvantage:

The cost is higher. The manufacturing process requirements for raw materials are relatively high. There are fewer supplier mdf capable of manufacturing such mdf product and fewer distributors dealing in such plates. CUZI mdf suppliers near me can provide you with high quality pine MDF.

Pine miscellaneous wood

It is a mdf board density that is machined by mixing pine and various hardwoods as raw materials. It is a kind of economical coated mdf board with a very wide range of applications. It can choose different grades for different purposes and has a high cost performance. This type of mf mdf board can be seen in most furniture and wood products.

12mm mdf sheet advantages

The 12mm mdf color is brown, dark brown. According to different uses, different processing techniques can be divided into different grades of mdf density. High quality pine mixed wood density board with fine fiber, good core layer and excellent physical properties, can be carved, milled, it is often used in the manufacture of furniture and craft wood products. If the performance requirements of the board are not high, such as making packaging boards, exhibition boards, etc, you can choose ordinary pine mixed wood density board.

Disadvantages:

This type of 12mm mdf has rich sources of raw materials and low processing technology requirements, so there are many brands on the market, with mixed good and bad. However, it is difficult to distinguish the grade and quality of the veneer mdf board based on its appearance alone. Try to choose a professional 12mm mdf board distributor when purchasing, you can get professional advice according to the purpose reduce the cost and the risks encountered in the later processing.

Poplar

It is a kind of density board made of poplar wood as the main raw material and mechanically processed. It is a common low-grade density

board.

Features

The finished plate is white and soft, and the fiber is thicker due to the influence of tree species. It is easy to fluff when carving and milling, and is not suitable for modeling. The swelling rate of water absorption thickness is relatively high, and it is easy to be damp. Because of its better color, it is often used as a decorative mdf sheet when the physical properties are not high.