Related Products

-

Marine Plywood

Marine plywood is defined as being produced in accordance with BS1088 marine plywood international standards, with environmental protection up to E0/E1 level.Get free samples

- About

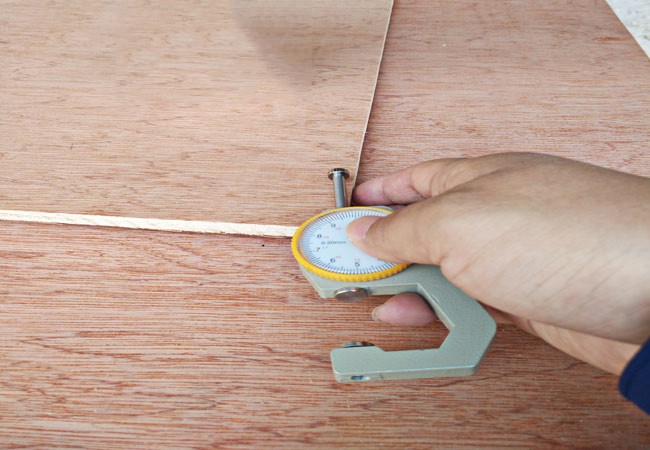

- Specifications

- Videos

BS1088

BS 1088 is the British Standard for marine plywood that applies to plywood produced with untreated tropical hardwood veneers that have a set level of resistance to fungus and water. The plies are bonded with Weather Boil Proof (WBP) glue. Normally the highest standards of WBP glue is Dynea resin from Norway.

Although bs1088 is a British Standard, the gaboon plywood does not have to be manufactured in Britain as long as the final products comply with the standard. The standard is associated with Lloyd’s Register since it performs testing of products to this standard.

WBP Glue Line

BS 1088 plywood must use an adhesive, which has been proven to be highly resistant to weather, micro-organisms, cold and boiling water, steam and dry heat.

Face Veneers

The face veneers must be free of knots other than “sound pin” knots, of which there shall be no more than six(6) in ANY area of one square foot. There can be no more than an AVERAGE of two such knots per square foot over the entire surface. The veneers must be reasonably free from irregular grain. The use of edge joints is limited, and end joints are not allowed.